What really is ACTIVATED CARBON?

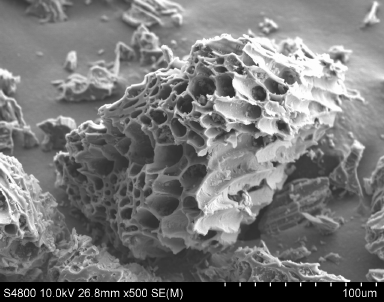

Activated carbon is charcoal that has been treated with oxygen to open up millions of tiny pores between the carbon atoms. Is the use of special manufacturing techniques results in highly porous charcoals that have surface areas of 300-2,000 square metres per gram. These so-called active, or activated, charcoals are widely used to adsorb odorous or coloured substances from gases or liquids.

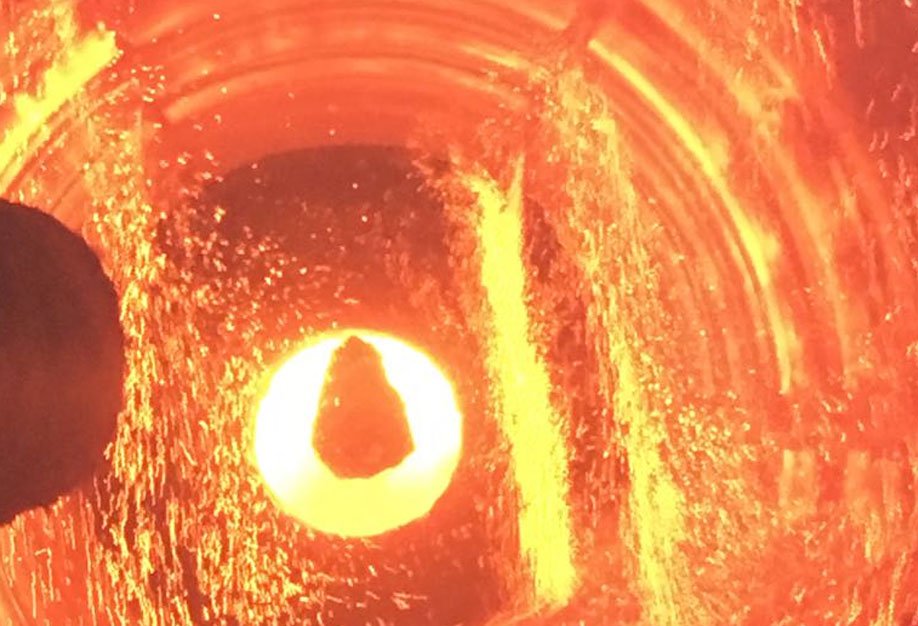

It is generally manufactured from carbonaceous raw materials such as high quality coals, coconut shells or wood, although other raw materials are constantly being investigated and developed.