Air & Gas Purification

(GAC 3x6, GAC 4x8, GAC 4x10)

Air & Gas

• Gas purification in the chemical sector and pharmaceutical industry

• Elimination of mercury and other contaminants in exhaust gases

• Collective protection filters for boats, vehicles and buildings

• Air filters for car cabins and rooms

• Extractor hoods used in universities, schools, hospitals and industrial laboratories

• Respiratory protection devices such as gas masks

• Compressed air filters for industrial air or high purity breathing air

• Elimination of specific contaminants in nuclear energy generation operations

• Evaporation control devices for vehicles.

• Solvent Recovery: Recovery of solvent from various plant like viscose rayon plant, magnetic tape plants, acetate plant etc

• Gas purification: Cleaning of process gas like hydrogen, natural gas, landfill gas etc

• Industrial air treatment: Capturing toxic gases like volatile organic compounds, hydrocarbon, Hydrogen sulfide, silixones gases from Petroleum, Paper, Coal fired thermal plant, Biogas, Waste Incinerators, Sewage treatment plant etc

• Protective Equipents(PPE):Respirators for Industrial workers and protecting them while exposed to VOC, acidic gases, basic gases, Ammonia in the work place

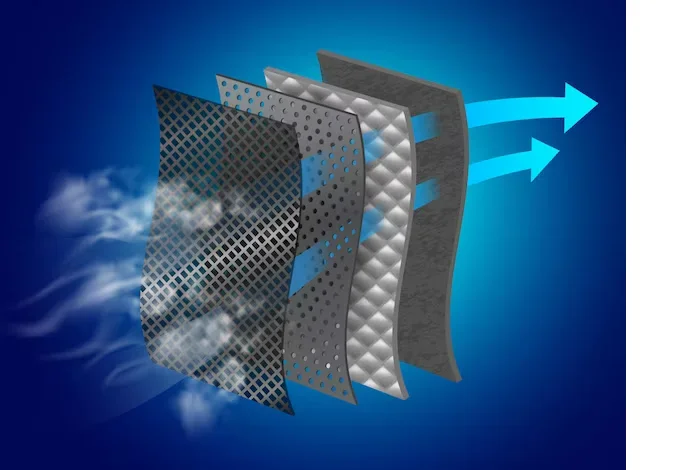

How it Works:The microporous structure of our coconut shell carbons is especially ideal for the removal of small molecules, such as volatile organic compounds. The activity is specified very precisely for each particular application and the high density and hardness provide a robust bed that withstands intensive use. Alternatively, in car or room filtration applications, its high purity and low dust content allows the carbon to be easily incorporated into a laminate material, which is pleated for maximum surface area with minimum pressure drop. The wide variety of impregnation treatments available increases the number of applications, which now includes many other organic and inorganic contaminants.

| Specification | Test Method | ||||

|---|---|---|---|---|---|

| Grade | ASTM D 2862 | 3x6 | 4x8 | 4x10 | 6x16 |

| Plus (%) | ASTM D 2862 | 5% max | 5% max | 5% max | 5% max |

| Minus (%) | ASTM D 2862 | 5% max | 5% max | 5% max | 5% max |

| CTC(%) | ASTM D 3467 | 50-60 | 50-60 | 50-60 | 50-65 |

| Surface Area,(m2/g) | BET | 1000-1150 | 1000-1150 | 1000-1150 | 1000-1200 |

| Moisture (%) | ASTM D 2867 | 4% max | 4% max | 4% max | 4% max |

| Ash (%) | ASTM D 2866 | 4% max | 4% max | 4% max | 4% max |

| Ball Pan Hardness (%) | ASTM D 3802 | 98 min | 99 min | 99 min | 99 min |

| Apparent Density (Kg/m3) | ASTM D 2854 | 470 +/- 30 | 490 +/- 30 | 490 +/- 30 | 510 +/- 30 |

| Ph | ASTM D 3838 | 9 to 11 | 9 to 11 | 9 to 11 | 9 to 11 |

| Specification | Test Method | ||||

|---|---|---|---|---|---|

| Grade | ASTM D 2862 | 8X16 | 8X20 | 12X20 | 30X60 |

| Plus (%) | ASTM D 2862 | 5% max | 5% max | 5% max | 5% max |

| Minus (%) | ASTM D 2862 | 5% max | 5% max | 5% max | 5% max |

| CTC(%) | ASTM D 3467 | 50-70 | 50-70 | 50-70 | 50-70 |

| Surface Area,(m2/g) | BET | 1000-1200 | 1000-1200 | 1000-1200 | 1000-1200 |

| Moisture (%) | ASTM D 2867 | 5% max | 5% max | 5% max | 5% max |

| Ash (%) | ASTM D 2866 | 4% max | 4% max | 4% max | 5% max |

| Ball Pan Hardness (%) | ASTM D 3802 | 98 min | 98 min | 98 min | 98 min |

| Apparent Density (Kg/m3) | ASTM D 2854 | 500 +/- 30 | 500 +/- 30 | 500 +/- 30 | 520 +/- 30 |

| Ph | ASTM D 3838 | 9 to 11 | 9 to 11 | 9 to 11 | 9 to 11 |