Dominican Republic's First Activated Carbon Manufacturer

Delivering Local Expertise, Reliability, &

Sustainable Solutions

Manufacturer and Exporter of high quality carbon products from Coconut Shell based Charcoal, and Coconut Shell based Steam Activated Carbon. The plant Started Operations in the year 2024 with the installed capacity of 2000 tons per year.Eco Carbon CCC is a company with Dominican and Puerto Rican capital.

We are located in the heart of the Caribbean, in the center of America, at a strategic point to supply any country on the continent. The Plant is located in San Cristóbal Dominican Republic, Calle la Coquera KM 5, Carretera Sánchez Vieja, Najayo Arriba.

We were born to become the most reliable activated carbon manufacturer on the American continent.

Mission

To produce high-quality activated carbon, using exclusively coconut from the Dominican Republic, taking advantage of its unique characteristics, highlighting the natural wealth of the Caribbean.

Vision

To be recognized as the innovative leader in the production of activated carbon in the US and Latin America, showing the world the quality and potential of the native Dominican coconut. Demonstrating that the Caribbean is not only a tourist destination, but also a benchmark in industrial quality.

Values

1. Authenticity: We take pride in our roots and in carrying the Caribbean spirit in every grain of activated charcoal we produce.

2. Superior Quality: Thanks to the thick shell of our coconut, we guarantee a product of maximum purity and efficacy.

3. Sustainability: We value our natural environment and adopt practices that protect and respect the environment, ensuring safety and health in our workplace.

4. Innovation with Tradition: We fuse modern technology with local resources, creating a product that is both traditional and advanced.

5. Commitment to Excellence: From the heart of the Caribbean, we work with passion and dedication to exceed the expectations of our international customers.

6. Respect for People: We give top priority to respecting each person as unique and valuable individuals. With that spirit in mind, we will seek to create and maintain an ideal workplace, where our business achievements are reflected in the growth of our people.

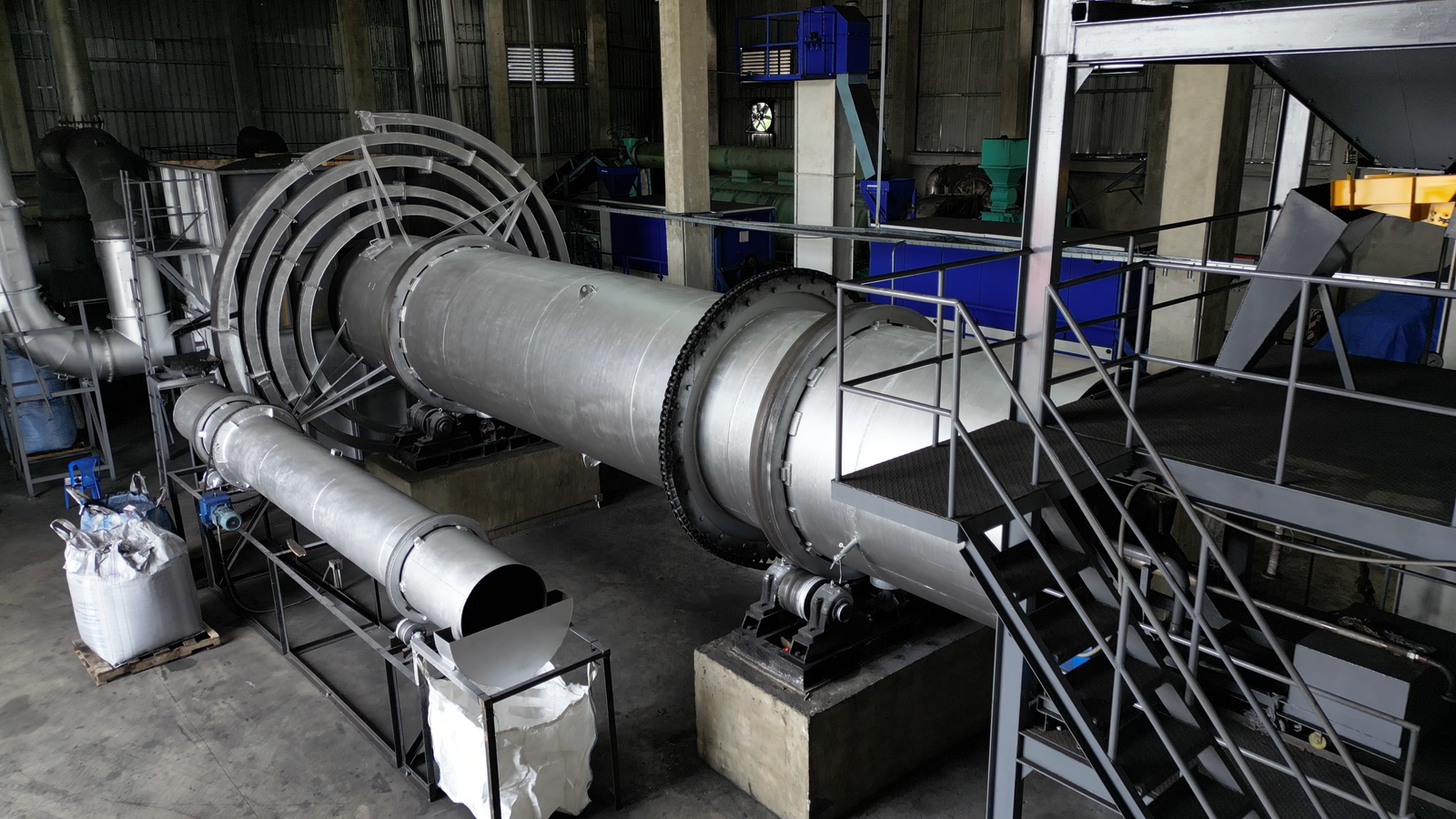

Eco Carbon virgin coconut based activated carbon products are made from high quality coconut shell charcoal. Eco Carbon has a dedicated carbonization plant and is able to maintain the quality from the raw material stage. The purest raw material is steam activated in a completely automated rotary kiln to manufacture high quality activated carbon. The whole process of manufacturing is done through trained professionals, Process control and quality control together with process automation is done in every stage of operation.

Our steam activated virgin coconut shell activated carbon suitable for air,water,metal recovery,decoloring,food and pharmaceuticals,energy storage application.

Eco Carbon focused on the production of activated carbon products suitable for the application of clean air and pure water. Pores developed in steam activation of coconut shell charcoal is best for the removal of volatile organic compounds from air and water high hardness of coconut shell activated carbon is best suits for metal recovery in Gold Industries. The ultra-pure carbon is suitable for decoloring in food and pharma industries.

• ECO Aquacarb

• ECO Filtercarb

• ECO Envirocarb

• ECO Colorcarb

• ECO PPEcarb

• ECO Goldcarb

To make the best product, the best raw material is required. This plant has been installed in the Dominican Republic precisely because the coconut from the Dominican Republic contains unique properties of thickness and resistance of the coconut shell, which allows us to achieve the best activated carbon in the world.

The charcoal fed into the activation process should be free from foreign particles and charcoal fines. This fibre dust from coconut shell, foreign material like sand, stones etc picked up during handling, unburned charcoal or semi carbonized charcoal are removed first. Next followed by granulation or crushing the dust free charcoal into uniform particle size depending upon the activation level in the Kiln.

This is the heart of the process. Here the granulated or uniform sized charcoal is feed in to the Kiln in a controlled feed rate, Steam is passed inside the Kiln to accelerate the activation process. Temperature of 850-950 degree is maintained in the Kiln depending upon the activation level required. CTC adsorption of 40-120% can be tuned during the process. The plant and machinery related to this process is shown below.

In this process the activated carbon from the Kiln is crushed and screened as per the customer requirement